As your business grows, navigating the complexities of logistics becomes crucial, and implementing effective logistics management strategies can make all the difference. Discover how streamlined operations can enhance customer satisfaction and drive your business forward in our latest insights!

# The Best Ways to Manage Logistics as a Growing Business

As a business evolves and expands, the complexities associated with logistics management inevitably increase. Logistics is more than just the transportation of goods; it encompasses the entire process of planning, implementing, and controlling the efficient flow and storage of goods from point of origin to point of consumption. Here, we’ll explore the best practices to effectively manage logistics as your business grows, ensuring streamlined operations and enhanced customer satisfaction.

Understanding the Importance of Logistics Management

Before delving into effective strategies, it's crucial to understand why logistics management is pivotal for a growing business. Efficient logistics can lead to:

- Cost Optimization: Reducing overhead costs through better inventory management and shipping strategies.

- Enhanced Customer Experience: Timely deliveries and quality service result in improved customer satisfaction and retention.

- Agility and Responsiveness: A robust logistics system allows a business to respond quickly to market changes and customer demands.

Before delving into effective strategies, it's crucial to understand why logistics management is pivotal for a growing business. Efficient logistics can lead to:

- Cost Optimization: Reducing overhead costs through better inventory management and shipping strategies.

- Enhanced Customer Experience: Timely deliveries and quality service result in improved customer satisfaction and retention.

- Agility and Responsiveness: A robust logistics system allows a business to respond quickly to market changes and customer demands.

Strategies for Effective Logistics Management

1. Invest in Technology

Technology plays a vital role in optimizing logistics. Various tools and software manage inventories, track shipments, and forecast demand. Consider the following technologies:

- Warehouse Management Systems (WMS): These help streamline operations by automating tasks related to inventory management, picking, and shipping.

- Transportation Management Systems (TMS): TMS solutions assist in planning, executing, and optimizing the shipment of goods.

- Real-Time Tracking: Implement GPS tracking for shipment monitoring, which enhances transparency and management.

Example:

A growing e-commerce business could use a TMS to optimize shipping routes, thereby reducing delivery times and logistics costs.

2. Optimize Your Supply Chain

An effective supply chain is critical to efficient logistics. Managing supplier relationships, assessing risks, and ensuring timely inventory replenishment are key components.

- Supplier Selection: Choose suppliers based on reliability, cost-effectiveness, and quality to maintain a solid supply chain.

- Risk Management: Identify potential supply chain disruptions and develop contingency plans.

- Inventory Management: Adopt Just-in-Time (JIT) inventory systems to minimize excess stock and reduce warehousing costs.

Example:

A retail business might implement a JIT system to ensure that inventory is received only as it is needed, reducing warehousing expenses significantly.

3. Streamline Transportation Logistics

Transportation is at the heart of logistics. Streamlining these processes can lead to significant cost savings.

- Consolidate Shipments: Combine multiple shipments to reduce transportation costs.

- Choose the Right Carriers: Assess and partner with reliable carriers that offer competitive rates and good service quality.

- Leverage Cross-Docking: This involves unloading goods from incoming shipments directly onto outbound trucks, reducing storage time and improving efficiency.

Example:

A manufacturer could work with a logistics provider that specializes in cross-docking to expedite delivery and lower transportation costs.

4. Implement Inventory Control Techniques

Effective inventory management is crucial as it affects almost every aspect of logistics. Consider incorporating the following control techniques:

- ABC Analysis: Classify inventory into three categories (A, B, and C) based on their importance. Focus on the top 20% of products that contribute to 80% of sales.

- FIFO/LIFO: Use the First-In-First-Out (FIFO) or Last-In-First-Out (LIFO) methods for managing the inventory flow according to product types.

- Cycle Counting: Regularly count a subset of your inventory to ensure accuracy and make adjustments as necessary.

Example:

A food distributor could implement FIFO to ensure that products nearing their expiry dates are sold first, thus minimizing waste.

5. Enhance Communication and Collaboration

Efficient communication across departments and with external partners is fundamental for successful logistics management.

- Centralized Communication Platforms: Use integrated communication tools for real-time updates on inventory levels, shipments, and order statuses.

- Collaborate with Suppliers: Engage in joint planning and share relevant data with suppliers to create a more synchronized supply chain.

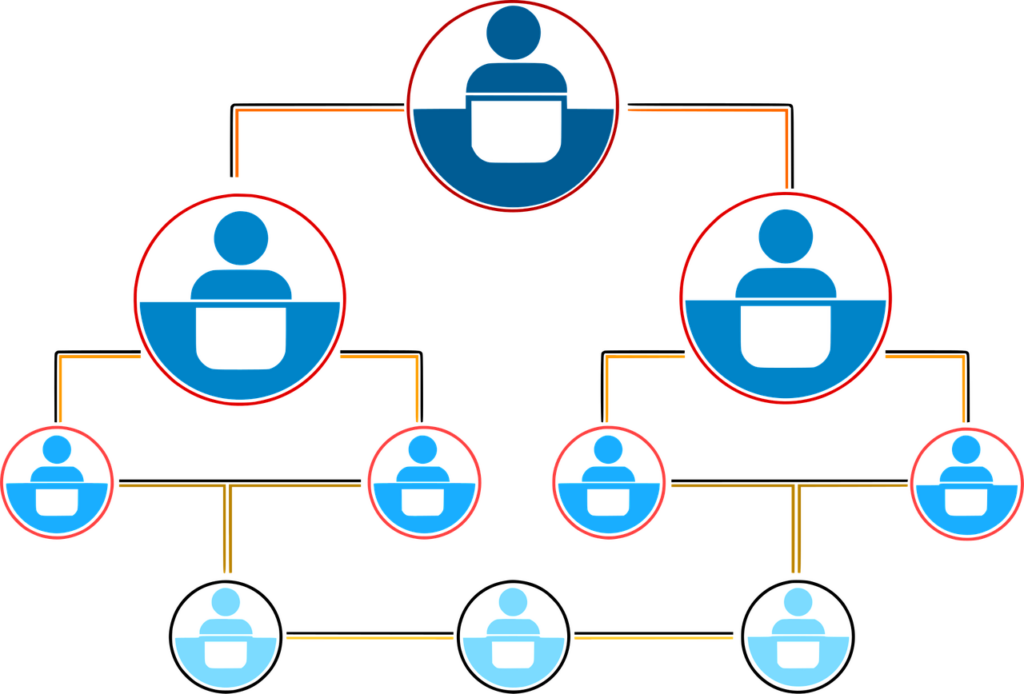

- Cross-Functional Teams: Establish teams that combine expertise from different departments (sales, operations, logistics) to streamline processes.

Example:

A company utilizing a centralized platform can enable sales and logistics teams to access real-time inventory data, minimizing the chances of stockouts.

6. Monitor and Adjust KPIs

Key Performance Indicators (KPIs) are vital for assessing the efficiency of your logistics operations. Regular monitoring allows businesses to identify areas for improvement.

Common KPIs to Consider:

- Order Fulfillment Time: The time taken from order placement to delivery.

- Transportation Costs: Costs associated with shipping products.

- Inventory Turnover: Measures how often inventory is sold and replaced.

Example:

Regular analysis of order fulfillment times can help identify bottlenecks in the shipping process, allowing for targeted improvements.

7. Sustainability in Logistics

With the increasing focus on sustainable practices, integrating eco-friendly logistics management can enhance your business's reputation and reduce costs.

- Eco-Friendly Packaging: Use recyclable materials for packaging items to reduce waste.

- Reduce Carbon Footprint: Optimize routes and consider alternative transportation methods, such as electric vehicles.

- Supplier Sustainability: Work with suppliers that prioritize sustainability to enhance your supply chain’s overall ecological impact.

Example:

A tech company adopting electric vehicles for local deliveries can significantly lower its carbon footprint while appealing to environmentally conscious consumers.

Conclusion

As businesses grow, the importance of effective logistics management becomes ever more pronounced. By investing in technology, optimizing supply chains, streamlining transportation, enhancing communication, and implementing sustainable practices, companies can position themselves for long-term success. By focusing on these best practices, businesses not only improve their own operations but also contribute positively to customer satisfaction and the environment.